Eco-friendly packaging, otherwise known as sustainable packaging, can best be defined as packaging that is sourced, created, and implemented to deliver minimal environmental impact.

In the recent past, companies that took the eco-friendly or green initiative were few. It was viewed as an alternative route to running your business while being mindful of the planet. While this was once perceived as a niche business practice, we are seeing this become the standard so that business’s environmental footprints can be lessened. Organizations are making this the new normal now more than ever, and Fulco Fulfillment Inc. is here to assist.

Using eco-friendly packaging and green packaging supplies is an ideal way to reduce the pollution and waste that eventually makes its way to landfills and oceans. Most, if not all, companies are looking to go green with their packaging today. Eco-friendly packaging in e-commerce especially can benefit the environment and economy.

Consumers are increasingly frustrated with receiving over-packaged products. By using right-size packaging for your e-commerce business, your company will display how much it cares about reducing waste. E-commerce fulfillment clients that are looking to hop on the sustainable bandwagon can source directly from FFI.

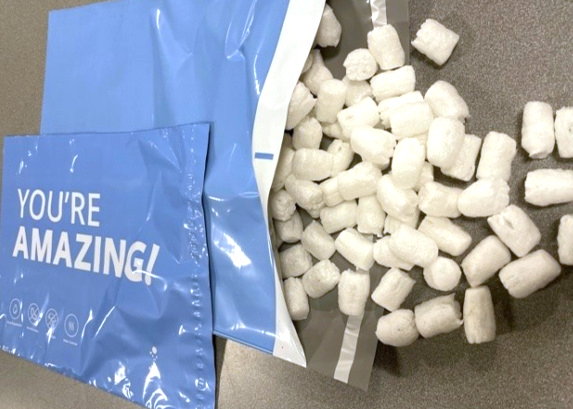

Fulco Fulfillment Sustainable Packaging Options Include:

- Biodegradable, zero-waste peanuts made of organic starch: they decompose in water and leave no toxic waste.

- Sustainable packing label envelopes made of 100% recycled polyethylene

- FFI offers ProLite Shippers and Duralit envelopes made of 35% recycled materials that are recyclable, waterproof, tear, and puncture resistant.

- Corrugated bubble wrap and recycled cardboard squares: a wrap made from up-cycled corrugated cardboard. Rather than disposing of cardboard, recycling it into corrugated bubble wrap gives it a chance at an additional life as a cushioning material.

- Air Pillows made of recycled materials: inflatable air pillows are used to fill voids while packaging. They can also be packed in boxes to secure loose items. This packaging consists primarily of air since they are small, inflated bags. They can be reused or recycled.

- Kraft Natural Reinforced Packing Tape

What is eco-friendly packaging?

As mentioned earlier, eco-friendly packaging is a green method of packaging that doesn’t deplete natural resources we have become so dependent on. The packaging is considered beneficial, healthy, and safe for both communities and individuals throughout the entirety of its lifecycle. It can be recyclable, compostable, reusable, made of biobased materials, or renewably sourced materials.

Eco-friendly packaging advantages:

Reduces your company’s carbon footprint.

Since sustainable packaging is better for the environment, it will reduce your company’s consumption of resources.

Improves your brand image

Using eco-friendly packaging shows that you care about the environment, creates a good impression, and depicts you as a responsible company.

Lighter packages reduce transport costs

Get ahead of the competition by reducing package material and preventing excessive waste. When this is implemented properly, you will notice storage being used more efficiently. With the extra space, you will be first and foremost lowering storage costs, and can increase the amount of products you want to store without going over budget or wasting space.

The marketing appeal of eco-friendly packaging

Customers are interested in switching their consumption habits so that they can lower their impact on the environment. Therefore, making the switch to sustainable packaging can help influence your customers when they decide which businesses to patronize.

Fulco Fulfillment is your Eco-friendly Packaging Partner

Eco-friendly packaging is a gateway to elevating your e-commerce business to the next level, and will start you on the sustainable path. By using eco-friendly packaging, you will be joining the cause in protecting our lands and oceans from accumulating single-use packaging. When you make the change to eco-friendly packaging, you will be using less material for your products. The lack of material will help you save money on storage costs, shipping costs, and packaging costs. It’s a savings trifecta that we recommend every business should choose.

If you decide to work with a professional fulfillment provider like Fulco Fulfillment Inc., we can assist with your switch to eco-friendly packaging at your business. While you focus on your e-commerce business, we will focus on making sure you are up to speed in this more sustainable world. To learn more about eco-friendly packaging, fill out our contact form or give us a call at 973-361-1700.

Box size

Box size Box shape

Box shape Box color

Box color  Box tape

Box tape Box filler

Box filler  Box content

Box content